How to Choose the Right Aftermarket Undercarriage Parts for Your Equipment?

Choosing the right aftermarket undercarriage parts for your equipment can be challenging. According to Paul Richards, an industry expert, “Quality in aftermarket parts is essential for effective machinery operation.” Understanding your needs is critical to making the right choice.

The market offers various options, each with its pros and cons. Components may differ in material quality and durability. Often, equipment owners overlook the importance of these differences. This oversight can lead to increased maintenance or premature equipment failure. Selecting the right parts requires careful consideration.

Consider factors like the type of machinery and specific working conditions. Cheap options may seem tempting but could lead to long-term issues. Investing in high-quality aftermarket undercarriage parts can save you money down the line. Evaluate your choices wisely to avoid common pitfalls.

Factors to Consider When Selecting Aftermarket Undercarriage Parts

Choosing the right aftermarket undercarriage parts is crucial for optimizing equipment performance. Several factors come into play during selection. First, consider the material quality. High-grade steel or reinforced composites often provide better durability. However, be cautious; some materials may not suit every application. Examine the type of work you perform and the surrounding environment. Certain materials may corrode or wear out faster in harsh conditions.

Next, focus on compatibility. Not all parts fit every model seamlessly. Research specifications carefully. Misfitting parts can lead to accidents or equipment failure. Don't forget to think about the supplier's reputation. Reliable suppliers often offer better warranties and customer support. A well-reviewed supplier is likely to provide parts that meet your equipment's needs.

Finally, reflect on cost versus value. Cheaper parts may save money up front but lead to costly repairs later. Sometimes, investing a bit more can yield better long-term performance. Understand the balance between price and long-lasting quality. In essence, taking the time to evaluate these factors can significantly impact equipment reliability. Make choices wisely; your equipment's future performance relies on it.

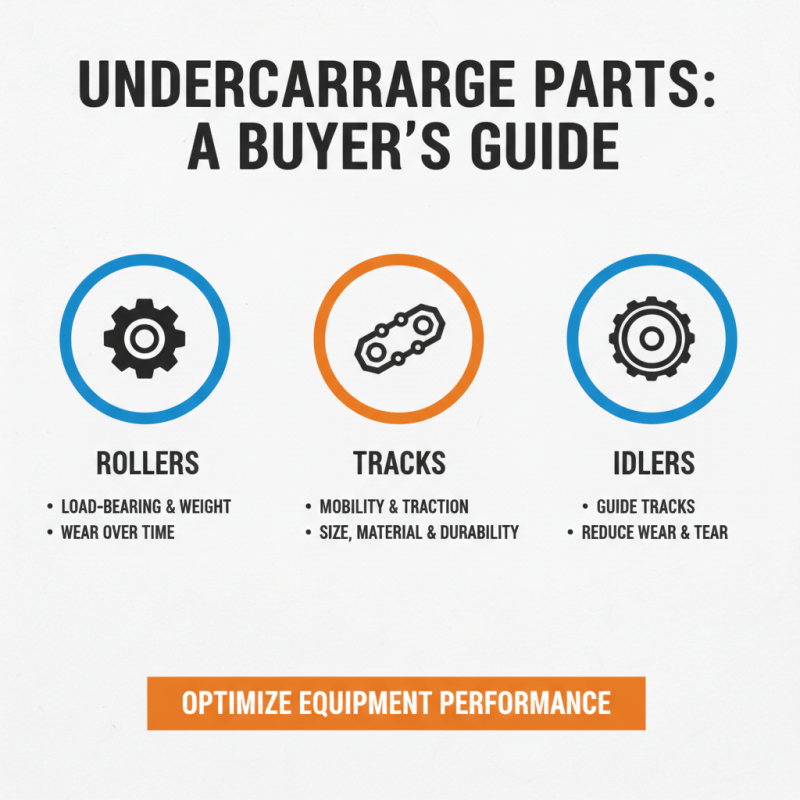

Understanding Different Types of Undercarriage Parts Available

When selecting aftermarket undercarriage parts, it’s essential to understand the different types available. Each component plays a specific role in ensuring your equipment operates efficiently. Common parts include rollers, tracks, and idlers. Rollers typically aid in load-bearing and weight distribution, often facing wear over time. Tracks are crucial for mobility. They come in various sizes and materials, impacting traction and durability. Idlers help guide the tracks, reducing wear and tear.

Materials matter greatly. Steel and rubber are popular options. Steel offers better durability but can be noisy. Rubber parts usually provide quieter operation but may wear out faster. It’s essential to weigh the pros and cons. Sometimes, a cheaper part may cost more in the long run due to faster wear. Questions about compatibility arise often. Not all parts fit every machine model. Always verify compatibility to avoid unnecessary delays.

Consider your work conditions, too. Are you on soft soil or rocky terrain? This choice can affect your undercarriage part selection. If you notice excessive wear, it may indicate the wrong part choice. It’s a learning process, and missteps can be valuable lessons. Always seek advice from experienced professionals to make informed decisions. It’s better to invest time now than regret a faulty choice later.

Assessing Compatibility with Your Equipment Model and Brand

When choosing aftermarket undercarriage parts, compatibility with your equipment model is crucial. Each piece needs to mesh perfectly with the existing components. A mismatch can lead to poor performance or even damage. Take the time to compare specifications carefully. Measure dimensions, weight capacities, and attachment methods.

It’s vital to check not only the model but also the brand and type of equipment. Some parts may look similar but have subtle differences. These differences matter in the long run. If you’re unsure, reach out to manufacturers for guidance. This can save you from costly errors.

Don’t overlook the material quality, too. A less robust part might seem attractive due to lower costs. However, this might lead to rapid wear and tear. A part that fits well but lacks durability will ultimately cost more. Finding the right balance between price and quality is key. Always ask for advice when in doubt. It might lead you to better choices.

Comparison of Aftermarket Undercarriage Parts Compatibility

Evaluating Quality and Durability of Aftermarket Components

When evaluating the quality and durability of aftermarket undercarriage parts, several factors come into play. A study shows that nearly 40% of equipment failures are related to these critical components. Selecting parts made from high-quality materials is essential. Components made from hardened steel typically exhibit better wear resistance. Statistics indicate that well-made aftermarket parts can outperform OEM counterparts in specific applications.

It’s important to consider suppliers who test their products rigorously. Reports reveal that around 30% of aftermarket parts fail to meet industry standards. Buyers should seek certifications that validate the manufacturing process. These could include ISO or ASTM certifications. These markers suggest a level of reliability that may be absent in cheaper options.

Moreover, installation quality affects durability significantly. A poorly installed part can fail prematurely, rendering it ineffective. Regular maintenance can catch issues before they escalate. Some equipment owners report that routine inspections help extend the lifespan of these components. Taking time to evaluate the reputation of suppliers can lead to better investment choices.

How to Choose the Right Aftermarket Undercarriage Parts for Your Equipment? - Evaluating Quality and Durability of Aftermarket Components

| Component | Material Quality | Durability Rating | Warranty Period | Price Range |

|---|---|---|---|---|

| Track Rollers | High Carbon Steel | Excellent | 3 Years | $150 - $250 |

| Sprockets | Alloy Steel | Good | 2 Years | $100 - $200 |

| Idlers | Cast Iron | Very Good | 4 Years | $80 - $150 |

| Tracks | High Strength Composite | Excellent | 5 Years | $300 - $500 |

| Bushings | Polyurethane | Good | 2 Years | $30 - $70 |

Cost vs. Value: Making Informed Decisions for Undercarriage Parts

When selecting aftermarket undercarriage parts, understanding cost versus value is crucial. Cost often appears as the deciding factor, pulling buyers toward lower-priced options. However, lower costs can lead to unexpected expenses down the line. Parts that wear out quickly may result in additional repairs or replacements. This can create a vicious cycle of spending.

Value isn’t just about the upfront price; it encompasses durability and performance. High-quality parts might seem expensive initially. Yet, they may offer better longevity and less downtime, ultimately saving money. It's not wise to focus solely on initial costs without assessing long-term benefits. Ask yourself: will these parts serve well over time?

No decision is perfect. Sometimes, a bargain may fail to deliver as expected. Research and seek feedback from peers in the industry. Stay aware of any red flags that suggest a part might not hold up. Balance cost with the expected performance to ensure you make informed and effective choices.

Related Posts

-

10 Essential Tips for Operating Heavy Equipment Safely and Effectively

-

How to Find the Best Earth Moving Equipment Rental for Your Project

-

10 Essential Tips for Operating Heavy Machinery Safely and Efficiently?

-

Why You Should Consider Earth Moving Equipment Rental for Your Next Project

-

Top Construction Equipment You Need for Successful Projects?

-

Top 10 Must-Have Construction Equipment for 2023 Projects