How to Choose the Right Construction Machinery for Your Project Needs

When embarking on a construction project, the selection of the right construction machinery is crucial to ensuring efficiency and effectiveness. According to industry expert John Taylor, a seasoned construction engineer, "Choosing the right construction machinery can make or break a project." With a vast array of machinery available, ranging from cranes and excavators to bulldozers and mixers, understanding the specific needs of the project is essential for making informed decisions.

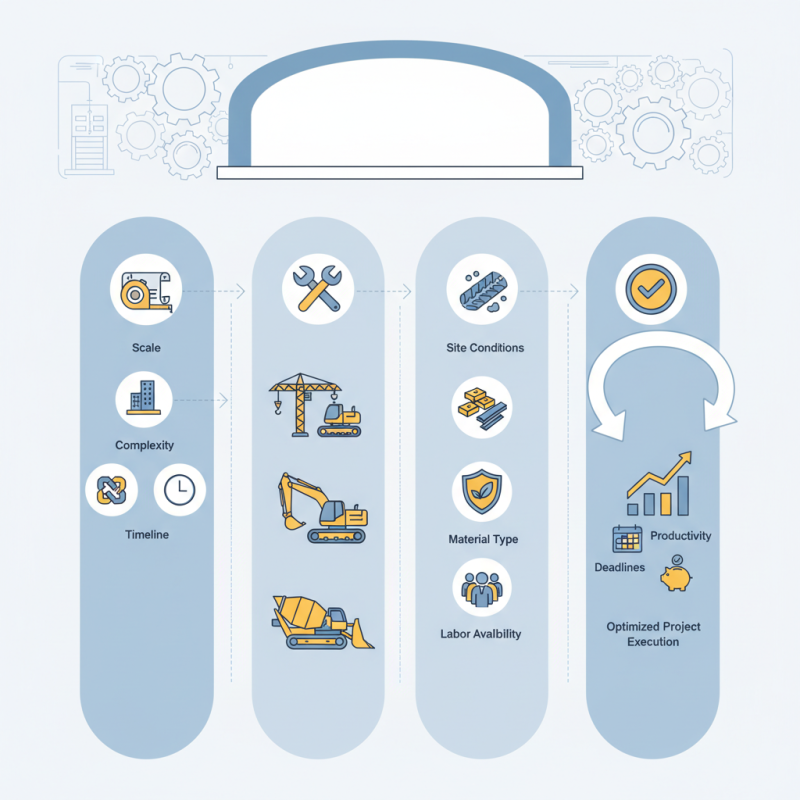

The first step in this process involves assessing the project's requirements, including the scale, complexity, and timeline. Each type of construction machinery serves a distinct purpose, and utilizing the appropriate equipment can significantly enhance productivity and safety on the job site. Taylor emphasizes that "misjudging machinery needs can lead to delays and cost overruns," making it imperative for project managers to evaluate their options carefully.

Furthermore, considering factors such as site conditions, material type, and labor availability will influence the machinery selection process. By balancing these elements, you can optimize your equipment choices, ensuring that your construction project progresses smoothly, stays within budget, and meets deadlines. Ultimately, understanding the importance of selecting the right construction machinery is a vital component of successful project execution.

Understanding Your Project Requirements and Specifications

When embarking on a construction project, understanding your project requirements and specifications is crucial for selecting the appropriate machinery. According to a report by the Construction Industry Institute, nearly 70% of construction projects face cost overruns primarily due to inadequate planning and equipment selection. This highlights the need for a detailed assessment of your project's unique demands, including the type of tasks to be performed, the site conditions, and the timeline.

Heavy machinery such as excavators, bulldozers, and cranes serve distinct purposes, and knowing the specifications of your project will dictate which equipment is necessary. For instance, a study from the National Utility Contractors Association indicates that projects requiring extensive groundwork may benefit more from compact excavators, especially in urban areas where space is limited.

Similarly, projects with significant lifting requirements may necessitate cranes with higher load capacities. Establishing a clear understanding of these factors not only optimizes efficiency but also minimizes potential delays and associated costs, which can average 10-20% of the project's total budget.

By taking the time to align machinery selection with project specifications, construction companies can enhance overall performance and ensure project success.

Evaluating Different Types of Construction Machinery Available

When evaluating different types of construction machinery for your project needs, it's crucial to first understand the various categories available. Heavy machinery such as excavators, bulldozers, and backhoes are essential for large-scale operations where soil movement and site preparation are required. These machines offer power and efficiency, making them suitable for tasks that involve digging, grading, and earth removal. Understanding the specific capabilities of each type of machinery helps in selecting the right one for your project.

Another important category to consider is the variety of lighter machinery and equipment that enhances productivity on smaller jobs. This includes tools like skid-steer loaders and compact excavators, which are ideal for confined spaces and residential projects. Additionally, specialized equipment such as concrete mixers or forklifts can offer significant advantages depending on the nature of the work being done. Evaluating the scale and requirements of your project will guide you in choosing machinery that not only meets operational demands but also aligns with potential budget constraints and efficiency goals.

Construction Machinery Types and Their Common Applications

Assessing the Cost and Budget for Machinery Selection

When embarking on a construction project, one of the foremost considerations is the cost associated with the machinery required. A well-defined budget acts as a guiding framework, helping to narrow down the options based on financial limits. It is essential to perform a thorough cost analysis that includes the initial purchase or rental cost, maintenance expenses, and potential operational costs over the machinery's lifecycle. Understanding the long-term implications of these costs can mitigate unforeseen budget overruns.

While evaluating the machinery options, it's vital to consider how their capabilities align with the project requirements. This involves assessing not just the price but also the efficiency and productivity levels expected from the equipment. Opting for machinery that is not only cost-effective but also suitable for specific tasks can enhance project outcomes and ultimately lead to better financial management. Prioritizing value over just upfront pricing ensures that the machinery chosen will fulfill its intended purpose effectively, resulting in a smoother project execution and safeguarding the overall budget.

How to Choose the Right Construction Machinery for Your Project Needs - Assessing the Cost and Budget for Machinery Selection

| Machinery Type | Daily Rental Cost ($) | Purchase Cost ($) | Maintenance Cost/Year ($) | Ideal Project Type |

|---|---|---|---|---|

| Excavator | 300 | 100,000 | 2,000 | Road Construction, Excavation |

| Bulldozer | 350 | 90,000 | 1,800 | Land Clearing, Site Preparation |

| Crane | 500 | 150,000 | 3,500 | High-Rise Construction, Heavy Lifting |

| Concrete Mixer | 200 | 30,000 | 1,000 | Concrete Works, Road Repair |

| Forklift | 250 | 25,000 | 800 | Warehouse, Material Handling |

Considering Equipment Size and Site Accessibility

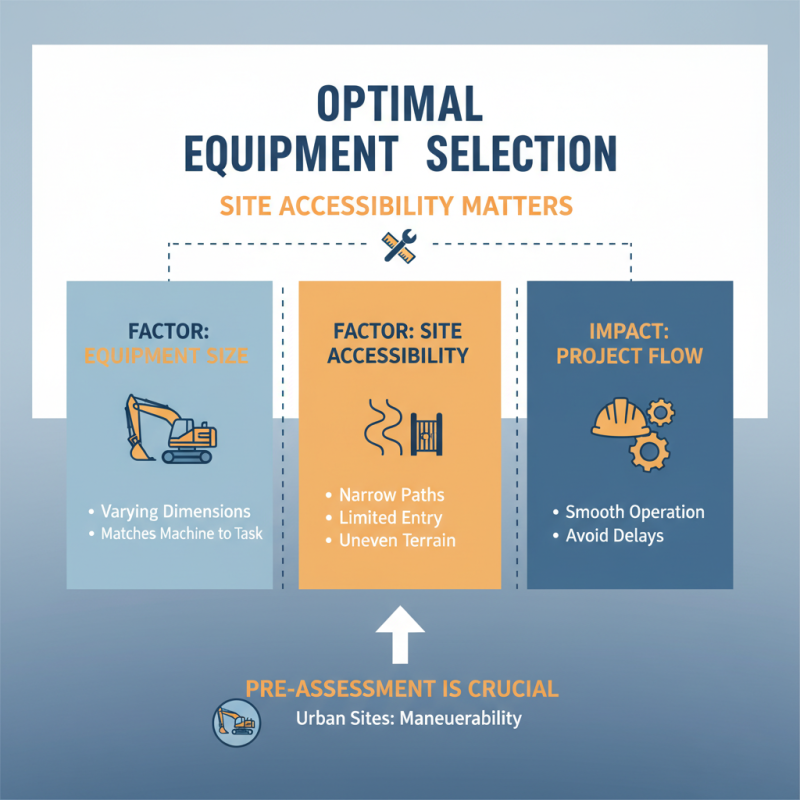

When selecting construction machinery for a project, one of the most critical factors to consider is the equipment size in relation to site accessibility. Different pieces of machinery have varying dimensions, and understanding the spatial constraints of your worksite is essential to ensure a smooth operation. Narrow pathways, limited entry points, and uneven terrain can restrict the types of machinery you can use. For example, a larger excavator may not be feasible in a crowded urban site, where maneuverability is key. Thus, conducting a thorough assessment of the site layout prior to making any equipment decisions is vital.

In addition to size, consider the physical characteristics of your site that could impact machinery movement. Factors such as the slope of the ground, overhead clearance, and surface stability will affect not only the selection of machinery but also its deployment. Equipment that requires extensive setup or stabilization may not be suitable for smaller sites, where time and space are of the essence. By prioritizing site accessibility and matching it with appropriately sized machinery, you can improve operational efficiency and reduce the risk of delays caused by unforeseen site challenges.

Reviewing Safety Standards and Compliance for Machinery Use

When selecting construction machinery for your project, understanding safety standards and compliance is crucial to ensuring a safe working environment. Machinery can pose various risks if not properly operated or maintained, making it essential to adhere to established safety guidelines. Familiarize yourself with the Occupational Safety and Health Administration (OSHA) regulations and any local safety codes that pertain to your specific machinery. Ensuring that all equipment meets these standards will help prevent accidents and promote a culture of safety on site.

Tips: Always conduct regular safety inspections of your machinery. This includes checking for any signs of wear and tear, ensuring that safety guards and features are intact, and confirming that operators are adequately trained in the equipment's safe use. Establish clear protocols for machinery operation and maintenance, ensuring that all team members are aware of their responsibilities.

Additionally, comply with manufacturers' recommendations regarding usage and maintenance schedules, as these guidelines are often designed to promote safe operations and extend the machine's lifespan. Encourage open communication among team members about safety concerns and engage in regular safety training sessions to reinforce the importance of adhering to safety protocols. By prioritizing safety compliance, you not only protect your workforce but also contribute to the overall success of your construction project.

Related Posts

-

How to Choose the Right Trackhoe Rental for Your Construction Project in 2025

-

What is Construction Equipment and How Does It Impact the Industry

-

Top 5 Must-Have Construction Equipment for Every Builder in 2023

-

The Future of Construction Equipment How Technology is Shaping the Industry

-

2025 How to Choose the Best Mini Excavators for Your Construction Needs

-

Top 10 Heavy Construction Equipment Every Contractor Should Consider for 2023