What is Equipment Parts and How to Choose the Right Ones for Your Needs

In the world of machinery and tools, selecting the right equipment parts is crucial for ensuring not only peak performance but also longevity. As noted by industry expert John Smith, "Choosing the correct equipment parts can mean the difference between operational efficiency and costly downtime." Understanding the purpose and functionality of various components helps in making informed decisions that cater to specific technical requirements.

Equipment parts encompass a vast range of items, from simple connectors to sophisticated electrical systems. Each piece plays a significant role in the overall efficiency of the machinery it supports. Hence, it is essential to consider compatibility, materials, and the intended application when making a choice. As machinery continues to evolve, so do the demands placed on these parts, transforming the selection process into a strategic task that can significantly impact productivity.

Navigating the complex landscape of equipment parts requires both knowledge and experience. Whether you are a seasoned professional or a newcomer to the field, understanding the fundamentals of what constitutes high-quality equipment parts can empower you to make the best choices for your particular needs. By prioritizing quality and application, one can ensure that their equipment performs reliably and efficiently, ultimately leading to greater success in any operational environment.

What Constitutes Equipment Parts in Various Industries?

In various industries, equipment parts play a crucial role in maintaining operational efficiency and ensuring the longevity of machinery. For instance, in the manufacturing sector, equipment parts can include bearings, gears, and conveyor belts, which are essential for the smooth functioning of production lines. According to a report published by the National Association of Manufacturers, the U.S. manufacturing sector alone is projected to grow by 3.4% annually, highlighting the increasing reliance on high-quality equipment parts to facilitate production processes and reduce downtime.

In the automotive industry, components such as engines, transmissions, and braking systems fall under the category of equipment parts. The Automotive Aftermarket Industry Association indicates that the automotive aftermarket industry is expected to reach $1.56 trillion by 2023, underscoring the significance of reliable equipment parts for vehicle maintenance and repair. Similarly, in the construction sector, equipment parts like hydraulic systems, excavator buckets, and safety gear are vital for ensuring projects are completed safely and efficiently. The Construction Industry Institute notes that equipment failures can lead to project delays and increased costs, which underscores the need for selecting the right parts for specific applications.

Choosing the right equipment parts requires a thorough understanding of one's specific needs and the environment in which the machinery operates. Factors such as material compatibility, load capacity, and environmental conditions should be carefully considered. Additionally, industry reports suggest that preventive maintenance and regular inspections can further enhance the lifespan of equipment parts, ultimately leading to lower operational costs and improved productivity.

Equipment Parts Usage Across Industries

Importance of Choosing the Right Equipment Parts for Performance and Longevity

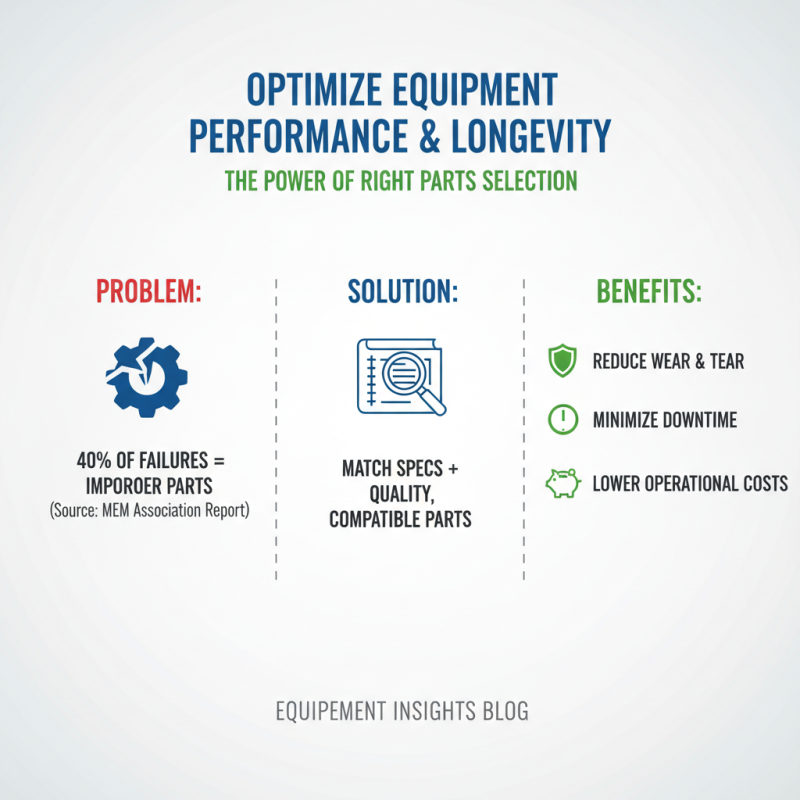

Choosing the right equipment parts is crucial for enhancing both performance and longevity in any machinery or device. According to a recent industry report by the Machinery and Equipment Manufacturers Association, nearly 40% of equipment failures can be attributed to improper parts selection. This underscores the importance of not only understanding the specifications of the equipment itself but also matching those with high-quality, compatible parts. High-performance parts can significantly reduce wear and tear, minimizing downtime and operational costs.

Moreover, selecting the appropriate parts can lead to a more efficient use of energy, which is increasingly important in today's environmentally-conscious market. The U.S. Energy Information Administration highlighted that machinery efficiency could be improved by up to 20% with the right components, translating to substantial cost savings over time. Equipment longevity is also influenced heavily by part quality and compatibility; well-chosen components can extend the lifespan of machinery by several years, ensuring better return on investment and reducing the frequency of costly repairs. By focusing on quality and the right fit, users can optimize their equipment for both performance and durability.

Key Factors to Consider When Selecting Equipment Parts for Specific Applications

When selecting equipment parts for specific applications, several key factors should be taken into consideration to ensure optimal performance and compatibility.

First, understanding the specifications and requirements of the machinery or equipment is crucial.

This includes the dimensions, weight capacity, and operating environment.

For example, parts that are designed for heavy-duty applications may need to withstand higher levels of stress and wear, while components used in sensitive environments may require materials that resist corrosion or contamination.

Another essential factor is the compatibility of the parts with existing systems.

Utilizing parts that are designed to integrate seamlessly with your current equipment can prevent operational issues and reduce maintenance costs.

Additionally, it is important to consider the manufacturer’s specifications and recommendations.

High-quality parts that are certified or tested for safety and reliability not only enhance the performance of equipment but also extend its lifespan, which translates to better long-term investment.

Lastly, it is advisable to evaluate the availability and lead time for the equipment parts.

Ensuring that parts can be sourced readily will minimize downtime and keep operations running smoothly.

Balancing these factors will help in making informed decisions when choosing the right equipment parts for any specific application.

Industry Standards and Certifications for Equipment Parts Quality Assurance

When selecting equipment parts, understanding industry standards and certifications is crucial for ensuring quality and reliability. Various organizations, such as the International Organization for Standardization (ISO), provide guidelines that help manufacturers and consumers alike evaluate the quality of equipment parts. For instance, ISO 9001 is a widely recognized standard that focuses on quality management systems. Adhering to such standards can significantly enhance product consistency and customer satisfaction. According to a report by the American National Standards Institute (ANSI), over 70% of companies that adopt industry standards experience fewer product failures and higher operational efficiency.

Furthermore, certifications such as the CE mark, which indicates compliance with European safety, health, and environmental protection standards, further reinforce the quality assurance of equipment parts. Research conducted by the International Electrotechnical Commission (IEC) shows that products certified under specific standards exhibit a 30% reduction in failure rates, thereby prolonging service life and improving safety. As consumers and businesses navigate their choices, recognizing these certifications can be pivotal in selecting the right parts that meet safety regulations and performance expectations, subsequently leading to reliable equipment operation.

Data-Driven Insights: Cost-Benefit Analysis of Equipment Parts Selection

When selecting equipment parts, performing a cost-benefit analysis is critical in making informed decisions that align with your operational requirements. This analysis involves evaluating the total cost of acquiring and maintaining parts against the benefits they provide in performance and longevity. For instance, while a higher initial investment in premium parts might seem daunting, the potential for increased efficiency and reduced downtime can lead to significant savings over time. Analyzing both direct costs, such as purchase prices, and indirect costs, like maintenance and replacement intervals, creates a clearer picture of the long-term value of your investment.

Another essential aspect is understanding the functional requirements of your equipment. Each component should not only fit physically but also meet performance specifications that can influence overall operational efficacy. By collecting data on previous part performance and operational outcomes, managers can make more informed choices that reduce the risk of unexpected failures. This data-driven approach encourages a thorough evaluation of options, allowing for the selection of equipment parts that enhance productivity while optimizing expenditures. Balancing initial costs with potential gains can lead to more strategic investments in your equipment ecosystem.

What is Equipment Parts and How to Choose the Right Ones for Your Needs - Data-Driven Insights: Cost-Benefit Analysis of Equipment Parts Selection

| Part Type | Average Cost ($) | Lifespan (Years) | Efficiency Rating | Maintenance Frequency (Months) | Cost-Benefit Score |

|---|---|---|---|---|---|

| Hydraulic Pump | 250 | 5 | 85% | 12 | 3.4 |

| Gearbox | 750 | 10 | 90% | 24 | 4.2 |

| Filter | 50 | 1 | 75% | 6 | 1.5 |

| Hydraulic Hose | 100 | 3 | 80% | 12 | 2.7 |

| Valve | 150 | 7 | 88% | 18 | 3.1 |

Related Posts

-

How to Choose the Right Trackhoe Rental for Your Construction Project in 2025

-

Top 10 Best Heavy Equipment Parts You Need for Optimal Performance

-

Top 10 Heavy Construction Equipment Every Contractor Should Consider for 2023

-

Top 10 Best Heavy Construction Equipment for Your Next Project

-

What is Trackhoe Rental and How to Choose the Right One for Your Project

-

How to Choose the Right Construction Machinery for Your Project Needs