10 Essential Tips for Operating Heavy Equipment Safely and Effectively

Operating heavy equipment safely is crucial in various industries. Many workers underestimate the risks involved. Heavy machinery can be dangerous if not handled correctly. Proper training and awareness are essential for safety.

When using heavy equipment, operators must stay focused. Distractions can lead to accidents. It is important to conduct regular inspections before use. These checks help identify potential issues that may arise. Ignoring them could result in costly mistakes.

Understanding the equipment's limitations is vital. Overloading or misusing machinery often leads to incidents. Each piece of heavy equipment has a specific purpose. Operators should respect these functions to maintain a safe working environment. Learning from past mistakes can lead to improved safety practices.

Understanding the Importance of Heavy Equipment Safety Standards

Heavy equipment safety standards are crucial in preventing accidents and ensuring optimal performance. Operators must understand these standards thoroughly. Each piece of heavy machinery has specific requirements. Ignoring these can have serious consequences. For example, improper training can lead to equipment misuse. This often results in injuries or even fatalities.

Moreover, regular maintenance is vital. A well-maintained machine operates more effectively and reduces risks. Visual inspections should become a routine part of any operator's day. Small issues can escalate into major problems if overlooked. There’s a temptation to skip this step when under tight deadlines, but the costs can be immense.

Emphasizing safety culture is essential. Operators should communicate openly about hazards. Not all workplaces foster this culture. Some may prioritize speed over safety. This mindset needs reflection and change. Encouraging safe practices creates a better environment for everyone. Each safety step taken is a step towards protecting lives.

Familiarizing with Operating Manuals and Manufacturer Instructions

Operating heavy equipment comes with significant responsibilities. Familiarizing yourself with operating manuals and manufacturer instructions is vital. Research shows that improper operation accounts for nearly 30% of equipment-related accidents. This highlights the importance of understanding the complexities of heavy machinery even before you step inside the cabin.

Reading the operating manual is not just a formality. It offers insights into safety features and emergency protocols. According to a study by the National Safety Council, the majority of mishaps could be avoided with better knowledge of equipment. For instance, knowing the load limits can prevent tipping accidents.

Here’s a tip: always conduct a pre-operation inspection. Check for hydraulic leaks and ensure all safety guards are in place. This simple step can save lives. Remember, it’s easy to overlook manuals amidst busy schedules, but that’s where mistakes happen. Engage with the material actively. Take notes and ask questions if uncertain. Embrace the process of learning; it’s essential for safe operation.

10 Essential Tips for Operating Heavy Equipment Safely and Effectively

| Tip Number | Tip Description | Importance | Frequency of Review |

|---|---|---|---|

| 1 | Read and Understand the Operator's Manual | Very High | Before Operating |

| 2 | Conduct Pre-Operation Inspections | Very High | Daily |

| 3 | Use Proper Personal Protective Equipment | High | Always |

| 4 | Be Aware of Your Surroundings | High | Constantly |

| 5 | Maintain Clear Communication Signals | High | Daily |

| 6 | Use Equipment for its Intended Purpose | Critical | Always |

| 7 | Secure Loads Properly | Critical | Before Each Move |

| 8 | Avoid Distractions While Operating | Very High | Always |

| 9 | Know Emergency Procedures and Equipment | High | Monthly |

| 10 | Keep Equipment Clean and Well-Maintained | Very High | Weekly |

Conducting Pre-Operation Inspections: Key Checklist Items

When operating heavy equipment, pre-operation inspections are crucial. They help ensure safety and efficiency. Begin with a thorough visual check of the machinery. Look for any visible damage or loose parts. Taking a moment for this glance can save hours of potential problems later.

Check fluid levels next. Hydraulic oil, fuel, and coolant are essential. Low levels might indicate leaks or maintenance issues. Make a habit of recording these readings. This helps track equipment health over time. Don’t ignore warning lights; they provide vital information about the machine's condition.

Inspect tires and tracks carefully. Look for wear, punctures, or debris. Proper tire pressure is needed to prevent accidents. A small oversight here can lead to significant consequences. Finally, ensure all safety features function correctly. Seat belts and alarms are often overlooked but vital for operator safety. Regularly checking these items can foster a culture of safety on the job site.

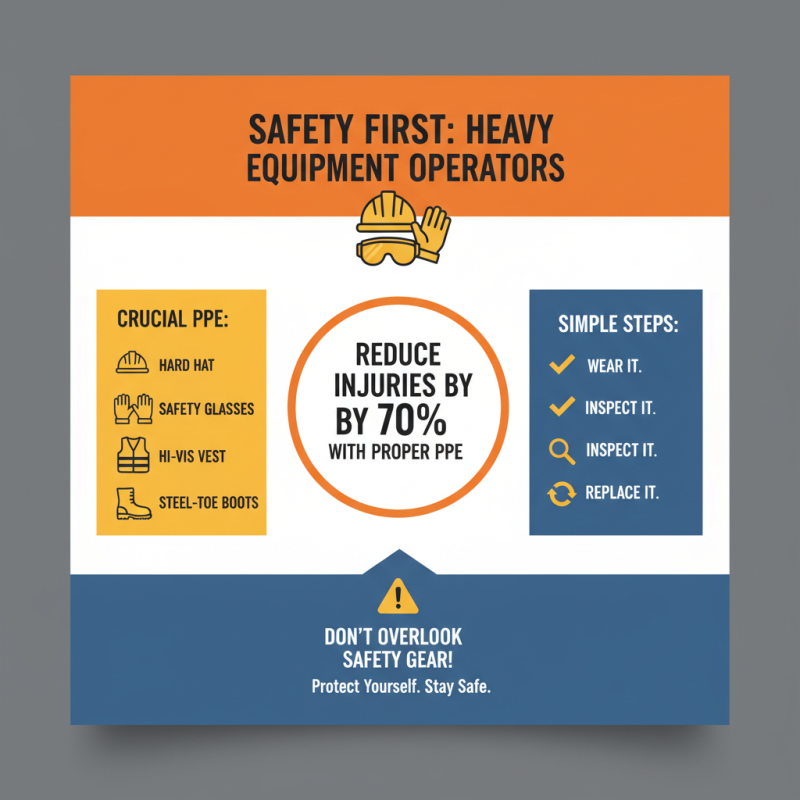

Utilizing Personal Protective Equipment (PPE) for Maximum Safety

Personal Protective Equipment (PPE) is crucial for heavy equipment operators. Studies show that using the right PPE can reduce workplace injuries by up to 70%. However, many workers still overlook this essential safety gear. Simple steps can enhance safety on the job site.

Wearing a hard hat protects against falling objects. Steel-toed boots prevent foot injuries from heavy equipment. High-visibility vests make operators more visible, especially on busy sites. Yet, a recent report revealed that only 50% of workers consistently use all required PPE. This is alarming and may indicate a lack of training or a culture that undervalues safety.

Regular training sessions on PPE usage can help. Engaging employees in discussions about their safety concerns may lead to better practices. The goal is to create an environment where everyone feels accountable for their own safety and that of their coworkers. Investing in proper PPE and training is no longer optional; it’s a vital part of operating heavy machinery safely and effectively.

Implementing Effective Communication and Signaling Procedures on Site

Effective communication is vital when operating heavy equipment. It ensures everyone on site understands their roles clearly. Visual signals can greatly reduce hazards. When a crane is lifting, hand signals might indicate when to stop or when to proceed. Miscommunication can lead to accidents. It’s essential to have clear guidelines.

Regular briefings help reinforce these practices. Use simple phrases and gestures. Everyone should be on the same page. However, relying on these signals alone isn't enough. Workers may forget instructions. Implementing regular checks can bridge this gap. Reinforce communication skills during training. This proactive approach can save lives. Too often, accidents occur because of assumed understanding.

Observing team dynamics is another key aspect. Sometimes, individuals may hesitate to speak up. A culture of openness is crucial. Encourage workers to voice concerns about visibility or noise. Addressing these issues can improve site safety. Ignoring communication barriers can lead to disasters. Taking these details seriously creates a safer work environment.

10 Essential Tips for Operating Heavy Equipment Safely and Effectively

Related Posts

-

The Future of Construction Equipment How Technology is Shaping the Industry

-

Top 10 Heavy Construction Equipment Every Contractor Should Consider for 2023

-

How to Choose the Right Trackhoe Rental for Your Construction Project in 2025

-

Top 10 Best Heavy Construction Equipment for Your Next Project

-

What is Trackhoe Rental and How to Choose the Right One for Your Project

-

Top 10 Tips for Choosing the Best Trackhoe Rental Service for Your Project