Top 10 Best Aftermarket Heavy Equipment Parts for Optimal Performance?

The performance of heavy machinery relies heavily on the parts that make them function. In the competitive construction and mining sectors, using high-quality aftermarket heavy equipment parts is essential. A recent report by the Association of Equipment Manufacturers highlights that nearly 50% of operators prefer aftermarket parts for cost efficiency and reliability.

When selecting aftermarket heavy equipment parts, the choice is vast. Quality can vary significantly. Operators often find themselves in a dilemma, balancing cost with performance. For instance, while cheaper alternatives may seem attractive, they sometimes lead to increased downtime or repairs. This can offset any initial savings. Ignoring this may lead to further complications down the road.

Moreover, the right aftermarket heavy equipment parts can enhance machinery longevity and functionality. However, not all parts deliver as promised. It’s crucial for operators to research and choose wisely. This diligence ensures optimal performance and reduces the risk of costly mistakes. Ultimately, understanding the aftermarket landscape is key to making informed decisions in heavy equipment maintenance and operations.

Top 10 Aftermarket Heavy Equipment Parts for Enhanced Efficiency

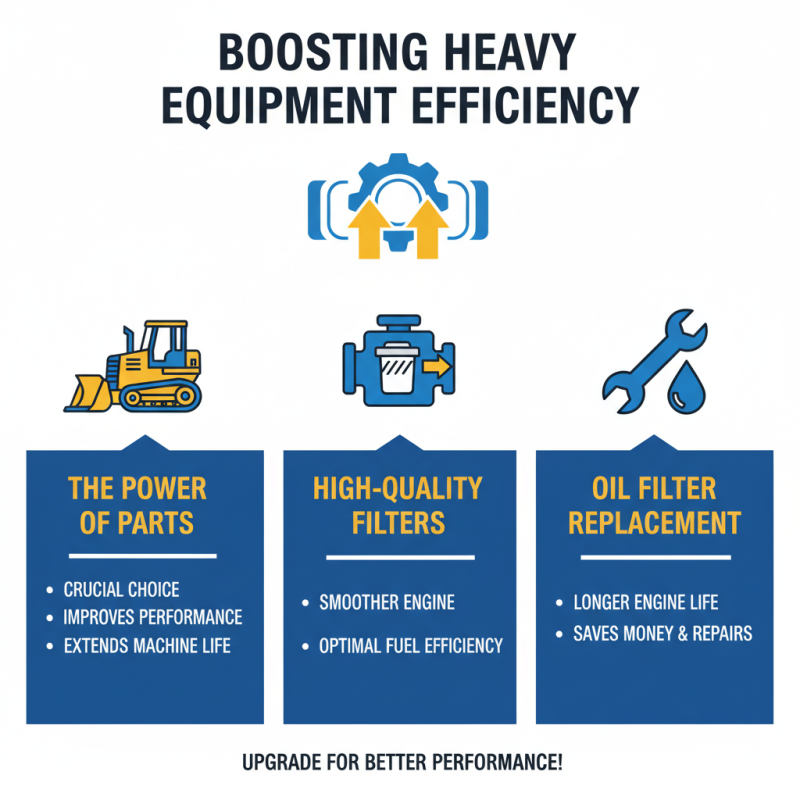

When it comes to enhancing efficiency in heavy equipment, choosing the right aftermarket parts is crucial. These components can significantly impact machine performance and longevity. For instance, high-quality filters ensure engines run smoothly, optimizing fuel efficiency. A simple oil filter replacement can extend engine life and save money in repairs.

Tips: Always check compatibility before purchasing parts. Misfitting components can cause damage. Consider buying from reputable sources to ensure quality. Look for parts designed specifically for your type of machinery. This often leads to better performance.

Another crucial part is hydraulic hoses. These are essential for proper operation in heavy machinery. Inspecting hoses regularly helps prevent leaks and sudden failures. Remember, even the best parts can underperform if not installed correctly. Pay attention to service manuals for guidance.

Efficiency is all about maintaining your equipment. Regular maintenance checks can identify potential problems early. Don't overlook worn belts or chains; they can affect the overall performance. Staying proactive saves time and money in the long run.

Key Factors Influencing Aftermarket Parts Selection and Performance

When choosing aftermarket heavy equipment parts, several key factors come into play. Quality is crucial. Parts should meet or exceed OEM standards to ensure reliability. Inspecting the materials used is a great starting point. Aftermarket parts must be durable. Without durability, performance suffers, leading to unplanned downtime.

Compatibility is another essential factor. The chosen parts should fit the equipment seamlessly. Installing incompatible parts can cause damage. This damage often results in costly repairs. It's wise to verify specifications and measurements before making a purchase. Sometimes, the perfect fit requires more research.

Lastly, consider the supplier's reputation. A trustworthy supplier can significantly impact performance. Seek reviews and feedback from other customers. While cost is important, the cheapest option may not be the best. Investing in quality aftermarket parts saves money in the long run. Reflect on these aspects before deciding. Making informed choices leads to better machinery performance.

Comparative Analysis of OEM vs. Aftermarket Heavy Equipment Parts

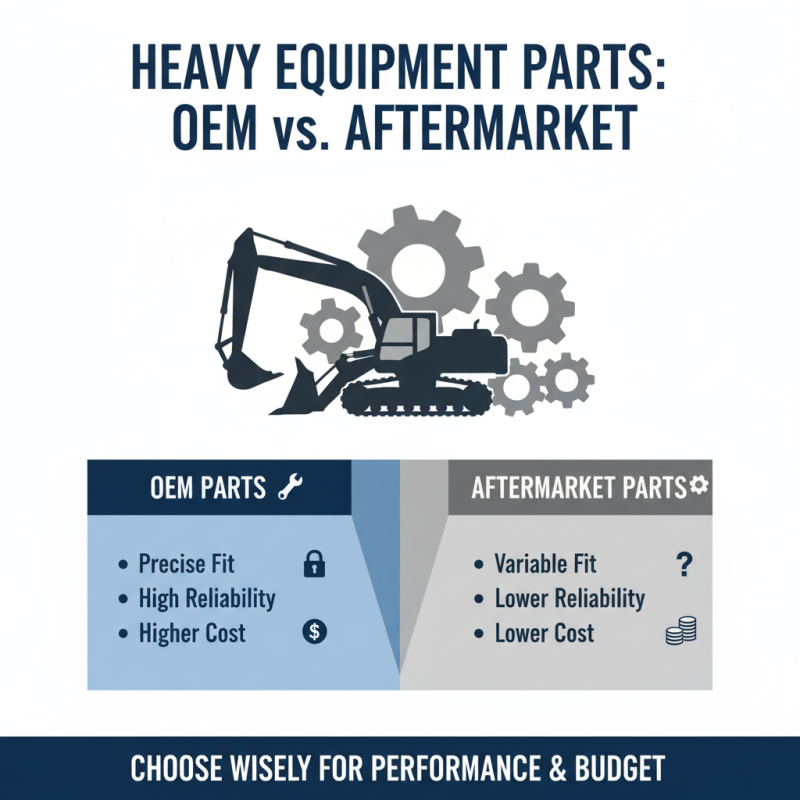

When it comes to heavy equipment, choosing between OEM and aftermarket parts can be challenging. OEM parts are designed specifically for the equipment they serve. This ensures a precise fit and high reliability. However, they often come with a higher price tag. For heavy machinery operators, the cost can be a significant factor in decision-making.

On the other hand, aftermarket parts provide a more cost-effective alternative. They are made by third-party manufacturers. Many of these parts boast similar quality and performance levels as OEM options. However, their variance in production standards can lead to inconsistent reliability. Some aftermarket components may not fit as perfectly and may require additional modifications. This inconsistency might lead to more downtime during equipment repairs.

Ultimately, the choice between OEM and aftermarket parts revolves around performance and cost. Operators must weigh the initial savings against potential long-term issues. This is a decision that requires careful consideration. A well-informed choice can enhance equipment longevity and efficiency. But it’s also an area where mistakes are common. Making the right call can save money and time down the road.

Impact of Quality Aftermarket Parts on Machinery Lifespan and Downtime

Using quality aftermarket heavy equipment parts can significantly enhance machinery performance. When equipment operators choose these parts wisely, they often see reduced downtime. This direct impact on productivity translates into increased efficiency on job sites. Operators can keep machines running longer without unexpected failures.

The longevity of heavy machinery is closely tied to the parts used in maintenance. High-quality aftermarket components can extend the lifespan of critical systems. However, not all aftermarket parts are created equal. Some may lack the durability needed for heavy-duty tasks. Choosing subpar replacements may lead to regrets down the line. It’s crucial to research and select parts with proven reliability.

Downtime can be costly for any operation. Quality parts help in minimizing repair times. When operators install durable aftermarket parts, they reduce the frequency of breakdowns. Yet, it’s essential to be vigilant. Regular inspections and maintenance ensure machines remain in optimal condition. This approach prevents minor issues from escalating into major repairs. Balancing cost and quality is a challenge but essential for effective machinery management.

Top 10 Best Aftermarket Heavy Equipment Parts for Optimal Performance

| Part Name | Impact on Performance | Lifespan Increase (%) | Downtime Reduction (%) | Cost Savings (%) |

|---|---|---|---|---|

| Hydraulic Cylinder | Improved lifting capacity | 30 | 25 | 15 |

| Engine Oil Filter | Enhanced engine protection | 20 | 15 | 10 |

| Brake Pads | Shorter stopping distance | 25 | 20 | 12 |

| Transmission Filter | Smoother shifting | 15 | 10 | 8 |

| Water Pump | Prevents overheating | 28 | 22 | 14 |

| Exhaust System Components | Better fuel efficiency | 18 | 10 | 20 |

| Shock Absorbers | Improved comfort and stability | 22 | 15 | 17 |

| Drive Belts | Improved power transmission | 35 | 30 | 18 |

| Seals and Gaskets | Prevent fluid leaks | 40 | 35 | 25 |

Industry Trends in Aftermarket Parts: Innovations and Best Practices

In the ever-evolving landscape of heavy equipment, aftermarket parts play a crucial role in maintaining performance and efficiency. Innovations in materials and design are reshaping this market. Many manufacturers are adopting advanced technologies like 3D printing to create more durable components. This trend enhances availability and reduces lead times, which is vital for construction projects.

Choosing the right parts can be challenging. Research is essential. Look for suppliers with a good reputation. Don't rush your decisions; a poorly made part can lead to costly downtime. Consider the specific needs of your equipment and check compatibility before purchasing. This careful approach is often overlooked.

Also, pay attention to maintenance practices. Regular inspections can identify wear and tear before it becomes a problem. This proactive strategy can save money and extend the life of your heavy machinery. Many operators find they overlook these details, which can lead to significant issues later. Always plan for the unexpected. Be prepared, and your equipment will perform optimally.

Related Posts

-

Top 10 Construction Trucks in 2023 for Heavy Duty Performance and Reliability

-

What are the Different Types of Heavy Machinery?

-

Top 10 Tips for Choosing the Best Trackhoe Rental Service for Your Project

-

Understanding the Lifespan of Construction Equipment Parts and Their Impact on Project Efficiency

-

Top 10 Volvo Construction Equipment Parts You Need for Optimal Performance

-

Why You Should Consider Earth Moving Equipment Rental for Your Next Project