Top 10 Construction Machinery Innovations Transforming the Industry

In the ever-evolving landscape of construction machinery, innovations continue to shape the way projects are executed and managed. As industry expert Dr. Emily Carter, a leading researcher in construction technologies, aptly states, "The advancements in construction machinery are not just enhancing productivity; they are redefining the capabilities of what we can achieve on-site." This sentiment encapsulates the transformative power of modern machinery that integrates cutting-edge technology, improving efficiency and safety in construction processes.

The surge in innovative construction machinery—from autonomous vehicles to advanced telematics—has revolutionized the industry, enabling companies to tackle complex projects with increased precision and reduced downtime. As construction demands grow worldwide, these innovations not only streamline operations but also pave the way for sustainable practices within the sector. In this exploration of the top 10 construction machinery innovations, we will delve into how these advancements are setting new benchmarks and fostering a dynamic environment for both seasoned professionals and new entrants in the field. The journey is not just about machinery; it is about embracing a future where operational excellence is within reach through technological ingenuity.

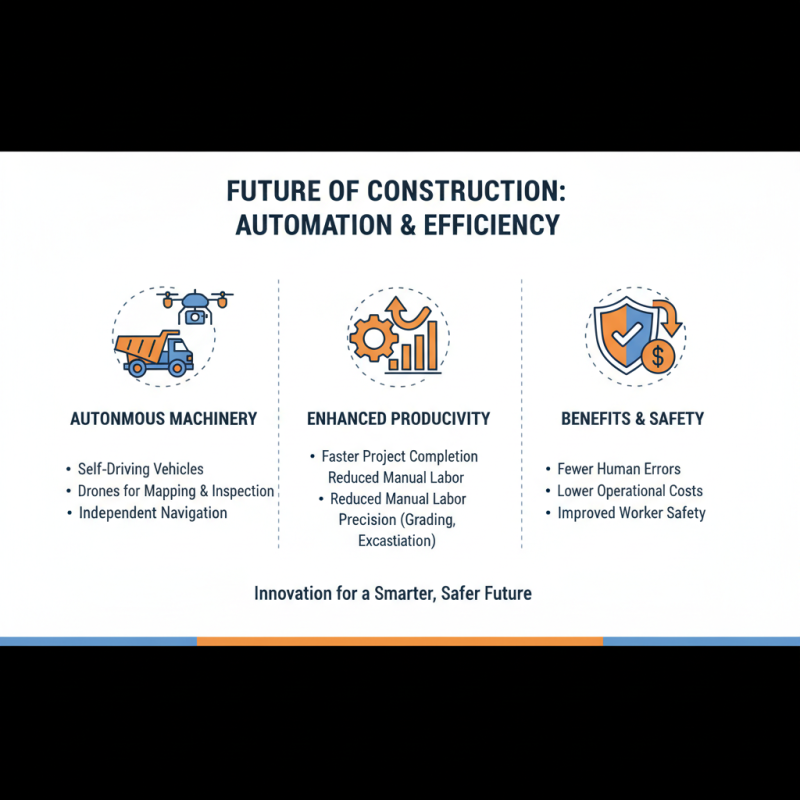

Revolutionizing Efficiency: Automation in Construction Machinery

The construction industry is witnessing a significant transformation driven by automation, enhancing efficiency and maximizing productivity. One of the most notable innovations is the development of autonomous machinery, which includes self-driving construction vehicles and drones. These machines can navigate job sites independently, reducing the need for manual labor while improving precision in tasks such as grading, excavation, and material transport. As a result, projects can be completed faster, and with fewer human errors, ultimately leading to lower costs and improved safety for workers on site.

Another key aspect of automation in construction machinery is the integration of advanced robotics and artificial intelligence. Robots are increasingly utilized for repetitive and hazardous tasks, such as bricklaying and demolition, allowing human workers to focus on higher-level decision-making and creative problem-solving. Furthermore, AI-driven software enhances equipment efficiency by predicting maintenance needs and optimizing operational workflows. This not only minimizes downtime but also extends the lifespan of machinery. Overall, the rise of automation is setting a new standard in construction, streamlining processes and paving the way for smarter, safer job sites.

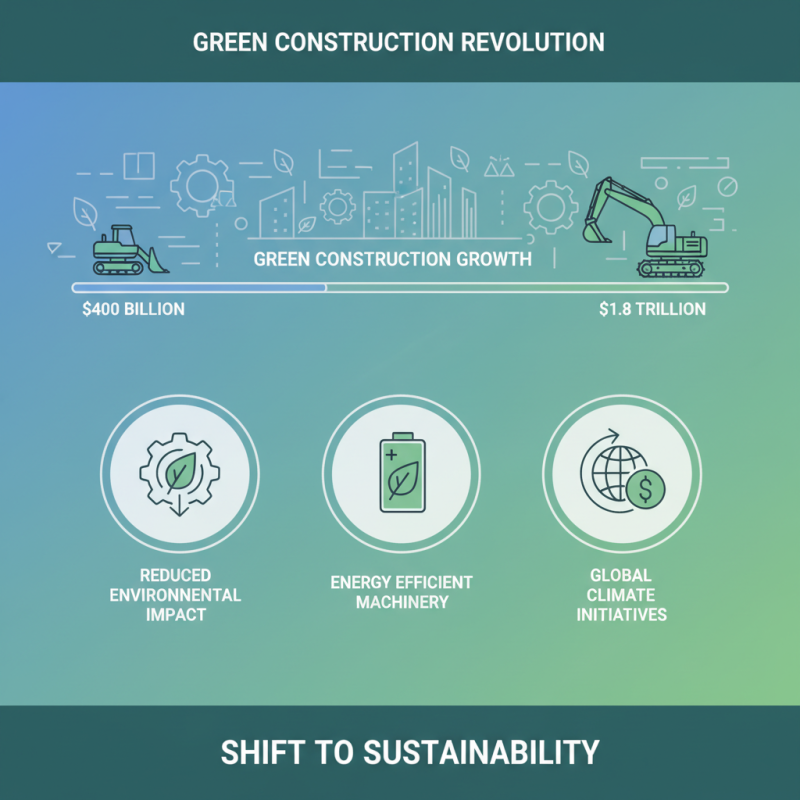

Sustainable Innovations: Eco-Friendly Machinery in the Industry

The construction industry is witnessing a significant shift towards sustainability, driven by the pressing need to minimize environmental impacts and embrace eco-friendly practices. Recent reports indicate that the global green construction market is projected to reach approximately $1.8 trillion by 2030, fueled by innovations in machinery that prioritize energy efficiency and resource conservation. This shift not only reflects a growing awareness among construction companies about their carbon footprint but also aligns with global initiatives to combat climate change.

Innovations in construction machinery are at the forefront of this transformation. For instance, the introduction of electric and hybrid-powered equipment has gained traction, with studies showing that electric machinery can reduce greenhouse gas emissions by up to 50% compared to their diesel counterparts. Additionally, advancements in automation and smart technology enable more efficient energy use and lower material waste on job sites. According to the U.S. Green Building Council, the integration of sustainable machinery not only boosts operational efficiency but also enhances the longevity and reduced lifecycle costs of infrastructure projects, making it a viable investment for forward-thinking construction firms. The embrace of eco-friendly machinery is thus crucial for fostering a sustainable future in construction, aligning operational practices with environmental responsibility.

Smart Technologies: The Rise of IoT in Construction Equipment

The construction industry is undergoing a radical transformation with the integration of smart technologies, particularly the Internet of Things (IoT). A report by the McKinsey Global Institute indicates that the adoption of IoT in construction can enhance productivity by up to 15%. IoT devices embedded in construction machinery enable real-time monitoring and data collection, leading to more informed decision-making and improved operational efficiency. For instance, sensors can track equipment performance, fuel consumption, and maintenance needs, allowing companies to reduce downtime and extend the lifespan of their machinery.

Moreover, the emergence of IoT in construction equipment facilitates predictive maintenance, which is critical to minimizing operational costs. According to a study by Deloitte, companies that implement IoT solutions for maintenance can see a 20% reduction in maintenance costs and a 50% decrease in unplanned equipment downtime. This proactive approach not only saves money but also increases safety on job sites by preventing equipment failures that can lead to accidents or project delays. As IoT continues to evolve, its impact on the construction industry is likely to expand, ushering in a new era of smart, efficient, and interconnected construction practices.

Enhanced Safety Features: Innovations Protecting Workers on Site

In the construction industry, the emphasis on worker safety has led to remarkable innovations that are transforming job sites. Enhanced safety features are no longer just an afterthought; they are integral to modern machinery design. Automated systems, such as collision detection and hazard alert technologies, help prevent accidents before they occur. Additionally, the integration of drones and AI-powered monitoring systems allows for real-time assessments of site conditions, ensuring that potential dangers are identified promptly.

When considering safety innovations, it’s crucial for companies to prioritize training and compliance. Implementing robust training programs can maximize the benefits of new machinery features. For instance, ensuring that all workers are familiar with safety technologies and protocols can significantly reduce risk. Establishing a culture of safety should involve regular updates on new technological advancements and how they impact operational procedures.

Another innovative aspect is the ergonomics of machinery. Enhancements in equipment design not only promote safety but also improve operator comfort, reducing fatigue-related accidents. Investing in ergonomically designed machinery can result in a healthier, more productive workforce. Companies should regularly assess their equipment to determine whether upgrades or replacements can further enhance safety and operational efficiency.

Top 10 Construction Machinery Innovations Transforming the Industry - Enhanced Safety Features

This bar chart illustrates the impact of various enhanced safety features on reducing workplace accidents in the construction industry over the past decade. The data shows significant improvements due to innovations such as better safety gear, machine automation, and enhanced site monitoring systems.

Advanced Materials: The Future of Lightweight and Durable Machinery

The construction machinery industry is undergoing a remarkable transformation, largely driven by advancements in materials that enhance the performance and durability of equipment. Lightweight yet robust materials like high-strength steel and advanced composites are paving the way for machinery that not only improves operational efficiency but also reduces fuel consumption. According to a recent report by the Construction Equipment Association, the use of advanced materials has contributed to a significant 25% reduction in equipment weight over the last decade. This shift not only facilitates easier transportation and handling but also elevates safety standards by allowing for better maneuverability on job sites.

Tips: When considering upgrades or purchases, focus on machinery equipped with advanced materials to maximize longevity and reduce operational costs. Many manufacturers emphasize the importance of durability and weight reduction in their latest models, making informed choices easier.

Moreover, sustainability is a driving force behind these innovations. The construction sector is increasingly embracing eco-friendly practices, and the use of advanced materials contributes to minimizing the environmental impact. For instance, lightweight machinery requires less energy to operate, resulting in a 15% reduction in carbon emissions on average, as reported by the International Energy Agency. This integration of sustainability not only meets regulatory demands but also enhances a company's reputation in an increasingly eco-conscious marketplace.

Tips: Keep an eye out for equipment that highlights its sustainability features. These advancements not only benefit the environment but can also lead to lower operational costs in the long term, creating a win-win scenario for businesses looking to thrive in a competitive landscape.

Top 10 Construction Machinery Innovations Transforming the Industry

| Innovation | Description | Impact on Industry | Future Potential |

|---|---|---|---|

| 3D Printing Technology | Utilizes additive manufacturing for creating components on-site. | Reduces waste and transportation costs. | Expected to enable full-scale building constructions in the future. |

| Robotics and Automation | Incorporation of robots for repetitive tasks on construction sites. | Increases efficiency and improves worker safety. | Potential to automate more complex construction tasks. |

| Drones | Use of UAVs for surveying, inspections, and monitoring. | Enhances site productivity and real-time data collection. | Further integration with AI for autonomous operations. |

| Smart Sensors | Integration of IoT devices for tracking machinery performance and health. | Improves maintenance schedules and reduces downtime. | Potential for predictive maintenance using data analytics. |

| Advanced Materials | Development of lightweight yet durable materials for machinery. | Reduction in fuel consumption and enhanced performance. | Continued innovation could lead to even stronger materials. |

| Augmented Reality (AR) | Use of AR for training and project visualization. | Enhances learning speed and project accuracy. | Could be widely adopted for on-site decision-making. |

| Sustainable Construction Practices | Innovative techniques to minimize environmental impact. | Aligns with global sustainability goals and regulations. | Potential to transform traditional construction approaches. |

| Telematics | Real-time tracking of equipment location and usage data. | Enhances operational efficiency and inventory management. | Future improvements may lead to better data-driven decisions. |

| Artificial Intelligence | Application of AI in project management and design. | Improves project planning and risk assessment. | Could revolutionize project execution and management. |

Related Posts

-

The Future of Construction Equipment How Technology is Shaping the Industry

-

What is Construction Equipment and How Does It Impact the Industry

-

Top 10 Heavy Construction Equipment Every Contractor Should Consider for 2023

-

Top 5 Must-Have Construction Equipment for Every Builder in 2023

-

Top 10 Best Heavy Construction Equipment for Your Next Project

-

Top 10 Must-Have Construction Equipment for 2023 Projects