Top 10 Excavation Equipment You Need for Your Construction Projects

In the construction industry, the efficiency and success of a project heavily depend on the tools and equipment utilized. Among these tools, excavation equipment stands out as a crucial element in various construction endeavors, from site preparation to land grading and trenching. According to a report by Research and Markets, the global excavation equipment market is projected to reach $59 billion by 2027, reflecting a compound annual growth rate (CAGR) of 6.3% from 2020. This growth underscores the increasing demand for robust machinery that can handle various terrain and soil conditions.

As noted by industry expert Emily Thompson, a renowned construction equipment analyst, "Choosing the right excavation equipment is fundamental in reducing project timelines and costs while ensuring safety and efficiency on the job site." Her insights highlight the importance of selecting appropriate machinery tailored to specific project requirements. With the right excavation equipment, construction professionals can optimize productivity and enhance the overall quality of their work.

In this article, we will explore the top 10 excavation equipment essential for your construction projects, detailing the features and applications of each to equip you better for your upcoming tasks. Whether you are a seasoned contractor or a newcomer to the industry, understanding these key tools will be invaluable in your construction pursuits.

Essential Excavation Equipment for Construction Sites

When it comes to construction projects, having the right excavation equipment is crucial for efficiency and safety on the job site. According to a report by a leading industry research firm, approximately 30% of construction delays are attributed to inadequate excavation practices and equipment. This underscores the need for essential excavation tools that can enhance productivity and minimize risks. Among the must-have equipment are excavators, backhoes, and bulldozers, each playing a pivotal role in site preparation and material handling.

Excavators, for instance, are versatile machines that provide significant advantages in terms of digging, loading, and grading materials. The same industry report indicates that the global excavator market is projected to grow by 4.4% annually, reflecting the increasing reliance on these machines for efficient excavation. Backhoes, on the other hand, are preferred for their multifunctionality in both digging and transporting materials within tight spaces. Meanwhile, bulldozers are essential for pushing large quantities of soil, making them invaluable for site clearing and leveling tasks.

Choosing the right excavation equipment not only accelerates project timelines but also addresses safety concerns associated with improper handling of excavation tasks. As noted in safety compliance statistics, improper equipment use leads to over 20% of construction site accidents. By investing in the right excavation tools and adhering to best practices, construction managers can significantly reduce risks while ensuring that projects are completed on time and within budget.

Types of Excavators and Their Specific Uses

Excavators are essential machines in construction and excavation projects, and they come in various types, each tailored for specific tasks. The most common type, the crawler excavator, is highly versatile and is ideal for heavy-duty applications like large-scale digging and demolition. According to a recent industry report, the global excavator market is projected to grow at a CAGR of 6% through 2025, driven largely by urbanization and infrastructure development. Crawler excavators can handle challenging terrains, making them perfect for construction sites with uneven surfaces.

Another significant type is the wheeled excavator, which offers mobility and speed, enabling it to travel on roads and work efficiently in urban environments. These machines are well-suited for landscaping tasks and site preparation, where agility is paramount. A report by Global Market Insights highlights that wheeled excavators account for approximately 25% of the market due to their efficiency in various settings. Furthermore, mini-excavators are increasingly gaining popularity, especially in residential projects, where space is limited; they provide the same power and utility as larger excavators while being compact and easy to maneuver. The ability to use attachments like augers and hydraulic breakers further enhances their versatility on job sites.

Understanding Attachments for Excavators

When it comes to maximizing the efficiency of excavation work, understanding the various attachments for excavators becomes essential. Each type of attachment is designed for specific tasks, providing operators with versatile options to tackle a range of projects. For example, a bucket is a fundamental tool that allows for effective digging, lifting, and transporting of materials. However, specialized attachments like grapples and augers offer enhanced capabilities for unique applications, such as handling heavy debris or drilling holes into the ground.

Moreover, investing in hydraulic breakers can significantly streamline demolition efforts, allowing operators to break concrete and other tough materials with ease. Similarly, using a tilt rotator attachment enhances the maneuverability and precision of the excavator, making it easier to work in confined spaces or perform intricate tasks. By selecting the right combination of attachments, contractors can adapt their machinery to meet the specific demands of each job, ultimately increasing productivity and reducing overall project timelines. Understanding these tools not only elevates the operator's skill set but also ensures that construction projects can be completed more efficiently and effectively.

Top 10 Excavation Equipment You Need for Your Construction Projects

Safety Considerations When Using Excavation Equipment

When it comes to excavation projects, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), over 60% of construction site fatalities are linked to excavation work. This alarming statistic emphasizes the importance of adhering to safety protocols when utilizing excavation equipment. Workers should always be trained in proper equipment operation and understand the potential hazards involved, which include trench collapses and hazardous underground utilities.

Preventative measures must be taken to mitigate risks associated with excavation. Implementing a comprehensive safety plan that includes regular equipment inspections can significantly reduce incidents. For instance, a report by the National Institute for Occupational Safety and Health (NIOSH) highlights that proper equipment maintenance can decrease the likelihood of malfunctions that can lead to accidents. Additionally, using protective systems such as trench boxes and sloping can provide essential support during excavations and safeguard workers from potential injuries. Prioritizing these safety considerations not only protects the workforce but also ensures the efficiency and success of construction projects.

Maintenance Tips for Longevity of Excavation Machinery

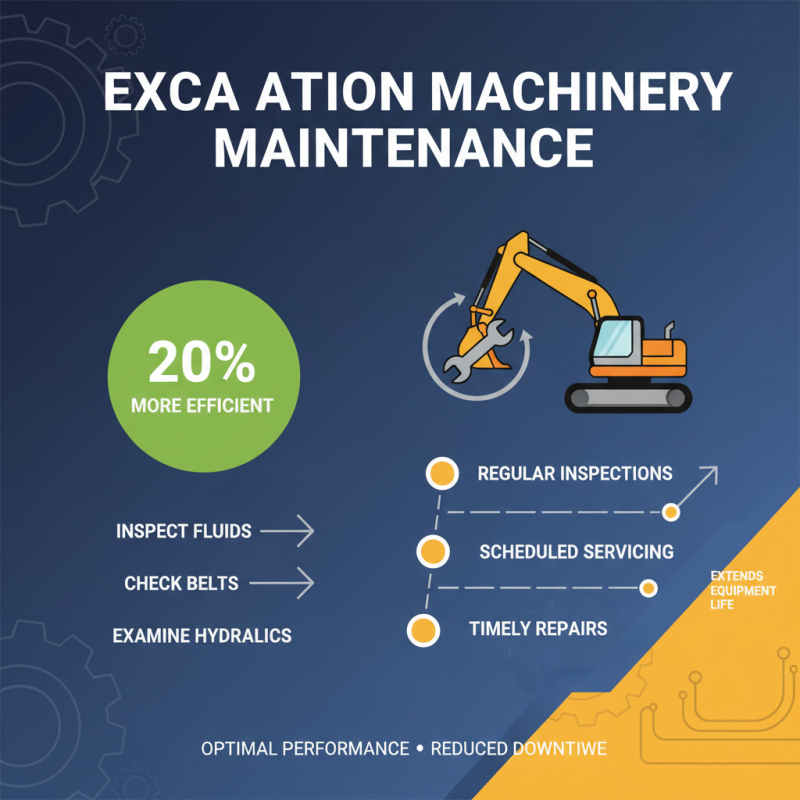

Proper maintenance of excavation machinery is crucial to ensure longevity and optimal performance in construction projects. According to a report by the Association of Equipment Manufacturers (AEM), well-maintained machinery can operate up to 20% more efficiently than neglected equipment. Regular inspections, scheduled servicing, and timely repairs prevent wear and tear that can lead to costly downtimes. Key maintenance activities include checking fluid levels, inspecting belts, and examining hydraulic systems. Implementing a proactive maintenance schedule can significantly extend the life of excavators and other heavy machinery.

Additionally, record-keeping of maintenance activities is essential. As per a study published in the Journal of Construction Engineering and Management, operators who meticulously document their machinery’s maintenance history are likely to experience fewer breakdowns and improved resale value. Utilizing telematics and diagnostic tools can enhance maintenance programs, allowing for predictive analytics that identify potential issues before they become critical. By investing in robust maintenance practices, contractors not only save on repair costs but also improve safety and productivity on site, leading to more successful project outcomes.

Related Posts

-

Top 5 Must-Have Construction Equipment for Every Builder in 2023

-

The Future of Construction Equipment How Technology is Shaping the Industry

-

Top 10 Heavy Construction Equipment Every Contractor Should Consider for 2023

-

How to Choose the Right Trackhoe Rental for Your Construction Project in 2025

-

Top 10 Best Heavy Construction Equipment for Your Next Project

-

What is Construction Equipment and How Does It Impact the Industry